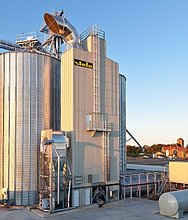

BTL 1-3000-22

in Great Britain

Product: SRF

Dryer output capacity:

SRF: 36 t/h from 20% to 10%

Industry solutions

Products

About stela

Contact

At stela, we offer customised modern solutions in the field of fuel pre-drying. By drying a wide range of alternative fuels, such as RDF (Refuse Derived Fuel) and SSW (Solid Shredded Waste), the controllability and quality assurance in clinker production is optimised. By using the waste heat from upstream production processes, the economic operation of the drying plants is guaranteed.

BTL 1-3000-22

in Great Britain

Product: SRF

Dryer output capacity:

SRF: 36 t/h from 20% to 10%

BT 1-6200-12

in Poland

Product: SSW

Dryer output capacity:

SSW: 10 t/h from 35% to 10%

BTL 1-3000-22

in Great Britain

Product: SRF

Dryer output capacity:

SRF: 36 t/h from 20% to 10%

BTL 1-3000-14

in Germany

Product: RDF

Dryer output capacity:

RDF: 8.9 t/h from 15% to 5%

BT 1-6200-13.5

in Latvia

Product: RDF

Dryer output capacity:

RDF: 7.7 t/h from 25% to 3%

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de

stela Laxhuber GmbH

Laxhuberplatz 1

D-84323 Massing

GPS coordinates:

North: 48.41839, East: 12.60456

Phone: +49 8724 899-0

Fax: +49 8724 899-80

Mail: office[at]stela.de

Web: www.stela.de

We use cookies on our website. Some of them are technically necessary, while others help us to improve this website or to provide additional functionalities.