Third generation (2014 - today)

2022

In June, stela celebrated its 100th anniversary. This event was gloriously celebrated with the band "LaBrassBanda" and around 900 invited guests.

2022

For the first time, to date stela received the biggest award in the company's history - the "Bayerischer Mittelstandspreis"

2022

In January, we break ground for our bays 7+8 to expand our warehouse space.

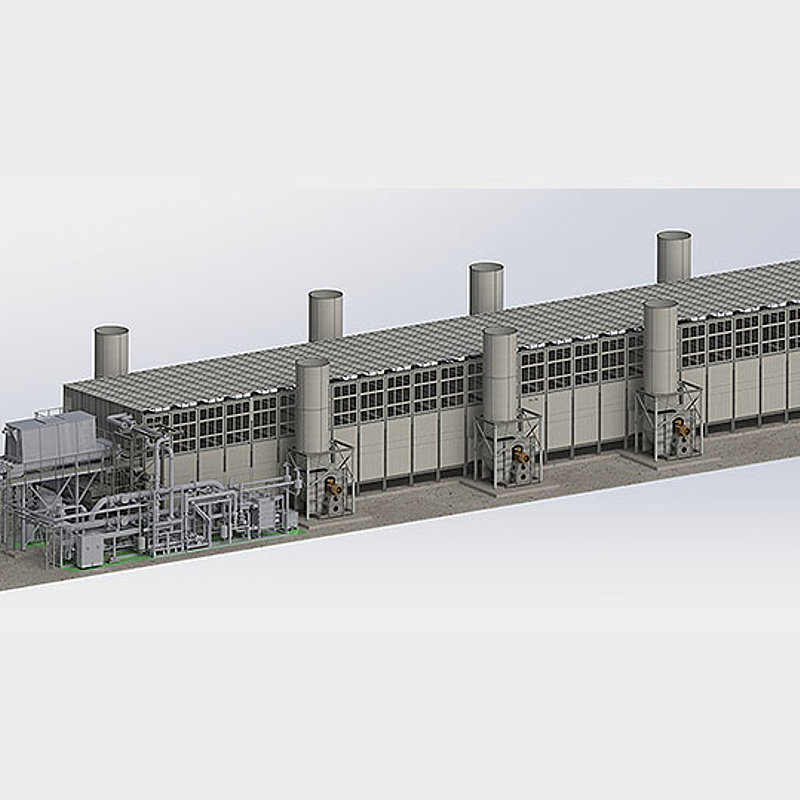

2021

A Brazilian power plant operator is using wood chips to generate energy. The chips must first be dried with a belt dryer system with an integrated hot water conversion station. This is based on a BT 1/8400-58 series model – the largest belt dryer produced to date, with a width of 8.4 metres. 100 tonnes of wet goods are dried per hour.

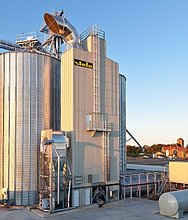

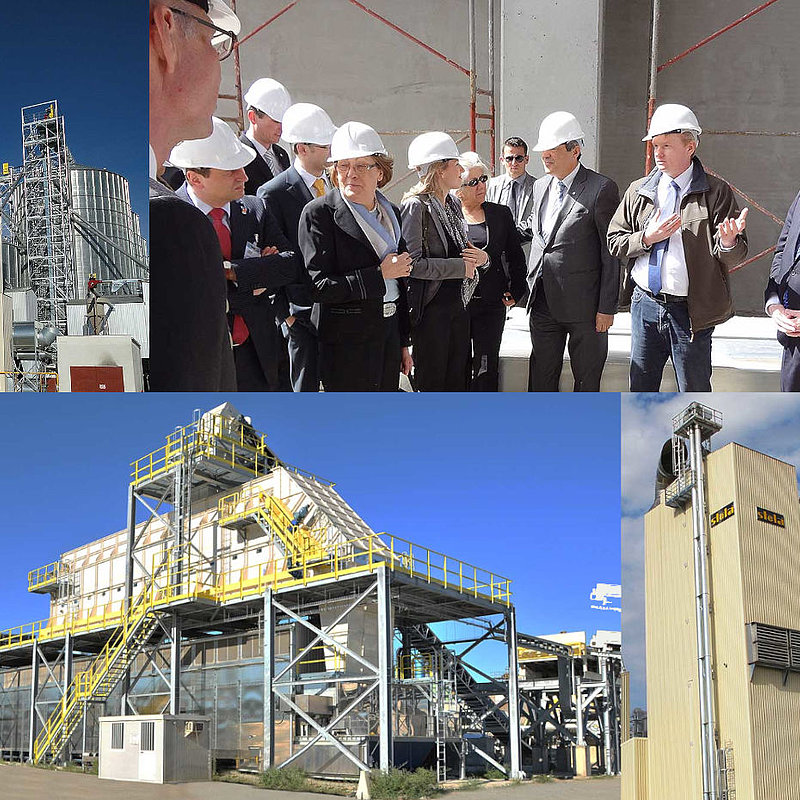

2018

For the second time in a row since 2017, stela Laxhuber GmbH is honoured as Top Company in Lower Bavaria. They are particularly commended for their work in training young people.

2017

A new development in technology for low-temperature belt dryers. The patented RecuDry system makes conventional drying technology even more efficient. This makes energy savings of up to 35–55% possible for new and existing systems.

2016

The company in Massing is bursting at the seams. After 16 months of construction, the company relocates to the new administration and production building in Morolding/Massing, right on the B388.There’s space for 140 employees, including 26 trainees, across 67,000m².

2014

Passing down to the third generation. Stefan Laxhuber proudly hands over the company to his son Thomas Laxhuber.

Second generation (1972 - 2014)

2013

A lot happens in 2013. The 200th agricultural drying system is sold to the Czech Republic. We look back on a long-standing and reliable partnership with Pawlica Grain Storage Technology. The same year, stela implement, in their own words, “one of the biggest projects in sewage sludge drying in the world” in Izmir/Turkey with their partner Haus from Istanbul. In Coniolo, Italy, I-PAN builds a new OSB plant – stela supplies the drying system. The first agricultural drying plant with patent-pending Biturbo technology is commissioned.

2009

Expansion is forging ahead despite the economic crisis. The first and biggest stela dryer ever produced is delivered to New Zealand. In Europe, the markets in Scandinavia and on the Iberian Peninsula are brought increasingly into focus. Stela succeeds in boosting its market share even further.

2008

The 1000th feed-and-turn-dryer system is delivered. This type of dryer has been the standard for more than 40 years. This system has proven itself today, particularly for the waste heat recovery from smaller biogas plants from 300 kW.

2002

Everything starts to move quickly. The third generation of Laxhubers begins construction of the first low-temperature sawdust belt dryer. This is the beginning of the success story that leads to market leadership in dryer systems for pellet production. In 2004, the world's first maize dryer with wood chip firing is built. In 2005, stela develops the first dryer systems for waste heat recovery from biogas plants. The belt dryers used can dry the digestate produced by using the waste heat from the biogas plant.

1997

The company celebrates its 75th birthday.Meanwhile, more than 2,000 drying plants are in operation all over the world. The opening to the East provides new sales opportunities for the future. Laxhuber GmbH is now the leading European manufacturer of belt dryers for food and industry.

1986

The production hall is expanded. In manufacturing, a welding robot complements the high technical standard. On average, 120 dryers leave the factory annually. The products of the STELA brand are shipped to every continent.In 1989, the company moves into a new administration building. The workstations are equipped with state-of-the-art computer systems and are interlinked.

1982

The company is set up as an independent company for switching systems, which were previously purchased from a third-party company. The regulations and requirements concerning the control technology of the dryer, which are becoming ever more complex, can now be achieved first hand with complete expertise.

1975

The first belt dryer for drying food creates a new field outside of agriculture.Maize threshers especially developed to harvest grain maize are imported from France.

First generation (1922 - 1972)

1972

On the 50th anniversary of the company, the founder Stefan Laxhuber hands over the company to his son.Delivery of the 500th Claas combine harvester is made. Many changes and improvements in drying technology follow in subsequent years. The systems are becoming ever bigger and more powerful.

1967

The first dryer for grain and maize is built. It is a flatbed dryer with the feed-and-turn system, still used today, under the brand name STELA. From this point forward, the slow but continuous changeover begins from selling purely third-party products to the manufacturing of the company’s own products.A year after the first dryer was built, a patent for the “Drying device for grain and similar cereals” is registered.The following year, a designer from Landshut, Mr Gedeck, designs the first brochures and the first stela company emblem.

1962

The company grows. The company celebrates its 40th birthday.It also delivers its 250th combine harvester. On this anniversary, a whole freight train with 30 Claas combines arrived in Massing.

1947

Over time, the company begins developing agricultural machinery. Stefan Laxhuber ranks among the pioneers of the new harvesting technology.In 1947, a hall to house the agricultural machinery is built. After the war, the reconstruction and, consequently, the mechanisation of agriculture that has been interrupted by the war starts up again slowly and gradually.

1922

In 1922, Stefan Laxhuber founds a small workshop in a garage in the centre of Massing. In this workshop, he carries out a range of metalworking tasks, from mending cooking pots and repairing water pumps to making mousetraps. As the water and electricity supply to the surrounding farms is very poor and the most modern technology is simple hand pumps at the well, Stefan Laxhuber soon starts building wind wells.