LIGNA 2023, the world's leading trade show for woodworking and wood processing, featured five days of innovation, inspiration and networking. From May 15 to 19, 2023, 1,300 companies from 50 countries presented their solutions for the wood and furniture industry, the woodworking trade and the primary sector. The focus was on the megatrends of sustainability and digitalization. The response from Germany and all over the world was correspondingly high. 80,000 visitors from 160 countries came to find out about smart machines and resource-saving production processes.

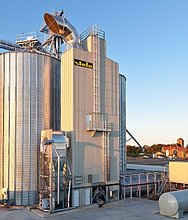

For the pellets industry, resource-efficient, reliable and flexible drying processes are the basis for sustainable production, which was the focus of this year's LIGNA. When it comes to energy efficiency and drying quality, the aim is always to achieve the maximum possible and to continuously adapt the benchmark of the technology to changing market conditions. to the changing market conditions. For more than 100 years, stela Laxhuber has been committed to this and in May presented its RecuDry® system with the latest technical standard based on many years of experience. At its LIGNA trade show booth, the market leader in the field of low-temperature belt drying will show its latest internationally realized projects. The focus is not only on future markets such as South and North America, but also on supplementing existing production lines with RecuDry® high-efficiency technology in Europe. A variety of heat recovery options and the use of the advantages of reliable automation will be shown, as well as the company's extensive know-how with different wood species, installation conditions and industries. The final drying of chips and OSB strands for the wood-based materials industry as well as internationally realized biofuels projects round off the range of applications in the biomass sector. The modular belt dryer system allows the operator to use various heating media. It is also flexible with regard to the initial moisture content of the material to be dried, without the drying result losing homogeneity. A number of new Stela developments in plant technology and thermodynamics enable the gentle drying technology to be used in a wide range of applications. The topic of our time - the saving of CO2 - is always in the foreground of the applications, not only from the area of pellet production, waste heat utilization from the energy center of the wood-based materials industry or the sustainable production of biofuels.