BT 1-6200-30

in Latvia

Product: Sawdust

Dryer output capacity:

Sawdust: 8.5 t/h from 50% to 10%

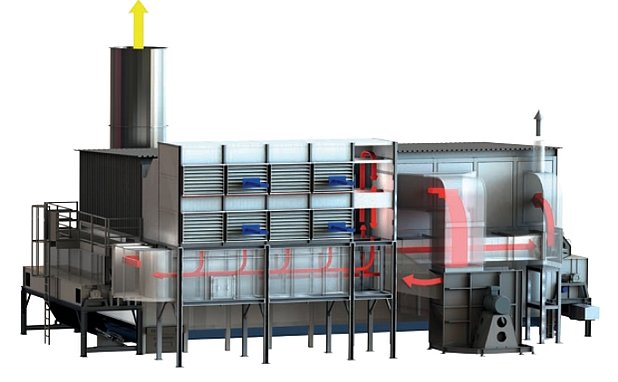

At the top, ambient air is fed through heating coils in the fresh air intake and thus heated. Depending on the local conditions, thermal oil, saturated steam, waste heat from combined heat and power and ORC processes or already heated process air can be used flexibly as heating media. By several dryer zones arranged in a row at this upper level it is possible to create drying areas with different process temperatures.

The dry material is evenly applied to the drying belt running underneath, which is made of an air-permeable, woven plastic material, via a double distribution screw. The warm air from the heating above is sucked down through this dryer belt, removing the moisture from the material on the belt.

In the extract air area below the belt, the moisture-saturated extract air is released into the environment.

Belt widths depend on the required water evaporation and can vary between 2 and 8.4 m, depending on the application Thanks to their enclosed design, they are also suitable for cold regions with outside temperatures down to -40° C. The capacity of the belt dryers is designed according to demand and is largely defined by the amount of water that the dryer is to extract from the material per hour. The systems are designed for capacities of 200 kg to 60 t of water per hour.

Air can flow through the process belts from above as well as from below. The belts can be zoned via the belt length. Several belts can be ventilated one after the other via the same air flow.

The dryers are available both as exhaust air and recirculation systems. Optionally, exhaust air heat recovery can also be implemented.

Download here our information brochure on low-temperature conveyor dryers.

It will give you an initial overview of our range and the variety of options available in this product category.

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de