MDB-XN 2-18-SU

in Ukraine

Products: Maize, Wheat

Dryer output capacity:

Maize: 50.8 t/h from 25% to 15%

Wheat: 104 t/h from 19% to 15%

Air heaters are of key importance for generating warm and hot air in the modern industry and agriculture. Especially in the agricultural and industrial sector they play an important role. Stela air heaters are suitable for a wide range of applications and they enable an efficient usage of many different fuels like oil, gas and renewable raw materials. Learn more about the different variants of Stela air heaters, their fields of utilisation as well as the technical features in the following.

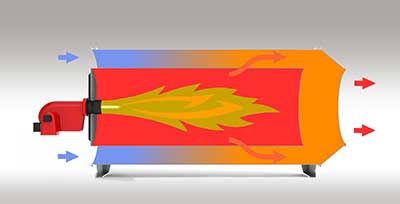

Direct Stela air heaters are used in the combustion of oil or gas fuels. They find utilisation in various industrial processes, but particularly in Stela drying plants and in the clinker and brick industry. The direct air heater consists of an outer casing, an intermediate casing to minimize the radiation loss, and a combustion chamber made from heat resistant material, which is centred in the casing. The combustion gases mix with fresh air at the combustion chamber wall, producing homogeneous hot air. The efficiency here is an impressive 100%.

Direct air heaters offer a range of advantages, that favour their use in industrial processes. Due to the direct contact between combustion gases and fresh air, the heat transfer is guaranteed, which leads to a fast and even heating. This is particularly important in applications such as Stela drying plants, where precise temperature control is required to achieve optimum drying results. In addition, the design of the direct air heater enables easy installation and maintenance, which further reduces operating costs.

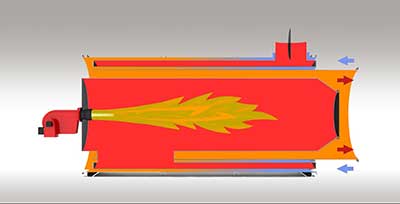

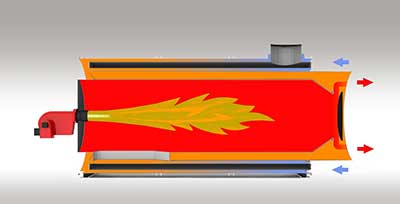

Indirect air heaters from Stela are used in processes where it is important that the flue gas does not mix with the air to be heated. They are TÜV-certified and meet even the strict requirements of the latest BImSchV with efficiencies of over 91%. All indirect air heaters can also be operated in direct mode, which further increases their versatility. The design of an indirect air heater is similar to that of a direct air heater, but the heating energy is transferred to the fresh air exclusively via the heat exchanger surfaces of the closed combustion chamber and the flue gas ducts. The cooled combustion gases are discharged outside via a chimney, which means that the hot air produced is completely free of flue gas.

Indirect air heaters for industry offer a number of advantages, which make them particularly suitable for demanding industrial processes. Separate routing of combustion gases and fresh air prevents contamination of the hot air, which is crucial in sensitive product environments such as food processing or pharmaceutical production. In addition, the flue gas-free warm air enables improved air quality in the workplace, which promotes the safety and well-being of employees.

Stela air heaters are indispensable components in agricultural and industrial processes, where the generation of warm air and hot air are of crucial importance. The direct and indirect variants each offer specific advantages that fulfil the requirements of different applications. With their efficiency, versatility and environmental compatibility, Stela air heaters are the ideal solution for heat generation in industrial processes.

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de