Whether at 35 °C in summer or in freezing cold in winter: the new Stela BTU RecuDry® low-temperature belt dryer with heat recovery dries sawmill residues at the HS Timber Group site in Kodersdorf, drawing the initial moisture content of around 50 % down to a residual moisture content of 10 %. Up to one third of the heating power can be saved and the system can be controlled as needed to reduce energy demand or throughput.

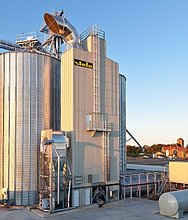

The HS Timber Group's sawmill in Kodersdorf, Saxony, can cut more than one million cubic metres of pine and spruce roundwood every year. With a planing capacity of 400,000 m3/year and an available drying volume of 600,000 m3/year, clearly a lot of energy is needed. In 2020, a CHP plant was installed to supply the plant with 5 MWel and 15.5 MWth to obtain and use this as optimally as possible. To ensure the best possible added value for the sawdust and wood chips produced during the cutting process, a pellet plant was also commissioned at the site in two expansion stages. This company produces ENPlus A1 premium pressings primarily for the German market, recognising that regional sales are sustainable and environmentally friendly. Initially, the pellets were made only from wood shavings, but now they are also made from sawmill residue with an original moisture content of up to 50 %. The choice of drying technology was also driven by the need to conserve resources: “For us, it was important that the drying of sawmill residues be as energy-efficient as possible,” says plant manager Thomas Kienz. That’s why they chose the BTU RecuDry® low-temperature belt dryer with heat recovery from Stela.

Energy-savings of up to 35 %

The generation and consumption of energy at the Kodersdorf plant varies with the time of year and the outside temperature. For the dryer to be able to work consistently – i.e. to dry up to 27 t of wet material per hour – the plant went for the RecuDry® system. This utilises the exhaust air from the drying belt, which is usually released into the open air, to generate energy. The drying material is dried from around 50 % to 10 % wood moisture content at 90 °C. The resulting exhaust air, which is 100 % moisture-saturated, still has a temperature of around 70 °C after the process. Stela makes use of this thermal energy. Instead of being released into the atmosphere, the wet air is fed into a wet air system. Fresh, dry air is then preheated by this exhaust air using heat exchangers. “This preheating allows us to save up to 35 % energy,” says Kienz. “And we can regulate the system depending on the outside temperature. We can operate with high system capacity in summer, when outside temperatures are high and heating energy demand is low. Vice versa, we save heating power in winter when temperatures are low because we do not have to heat the air from below zero to operating temperature; we just have to compensate for the temperature difference. This of course means a noticeable reduction in the heating power needed for the dryer.”

Comprehensive economic and energy efficiency

The three recondensation modules can be controlled independently of each other so that the reverse situation can also be handled; that is, if little energy is required for drying because of high outside temperatures. This allows the system operator to set the energy efficiency of the belt dryer as required. If there is sufficient thermal energy, recondensation can be switched off and the throughput of the dryer can be increased further. At Stela, the focus is on the entire process and genuine cost-effectiveness. One of the manufacturer’s fundamental aims is making CO2 savings. This was achieved in Kodersdorf using a system control with real-time parameters. This control system aims to produce only as much heat as necessary to meet the current needs with pinpoint accuracy.

Let winter come

The final installation steps were completed in the summer of 2021, “We are completely satisfied with Stela’s role in the support and installation of the belt dryer and now with the commissioning,” says Kienz. The company group has already had positive experiences with Stela dryers at its Romanian locations. The professionalism and cooperative partnership was therefore no surprise. Kienz is optimistic that the dryer will pass its fire and cold test in the coming winter with the required efficiency and the usual reliable support from Stela.