STELA Steuerungstechnik GmbH & Co. KG and STELA Laxhuber GmbH

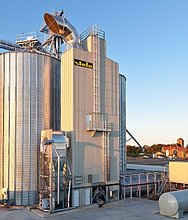

STELA Laxhuber GmbH is a third-generation, internationally-focused company that is active in the field of drying technology, which has its headquarters and production facilities in Massing. During the company’s 95-year history, more than 4,000 STELA drying systems have been delivered and commissioned in over 60 countries.

STELA wants to offer its clients the best possible technology, which is why we have specialised in drying. All our know-how goes into the development of state-of-the-art drying systems in a wide variety of sectors – from agriculture to the food industry, energy technology to waste disposal engineering. Specialising in drying as our core business has allowed us to grow continuously for years, both nationally and internationally. The drying systems are manufactured to customer specifications and designed in our own research and development laboratory to meet individual requirements. Our professionalism and continuous development have enabled us to establish ourselves as the market leader in low-temperature drying. Our customers include major agricultural companies, contractors, warehousing companies, cooperatives as well as industrial processing companies in the grain industry. Our low-temperature belt dryers, for example, are used in the production of wood pellets, as well as in the drying of fermentation residues and sewage sludge. STELA drying systems can now be found on every continent.

STELA Steuerungstechnik GmbH & Co. KG

Since its formation in 1982, STELA Steuerungstechnik GmbH & Co. KG in Massing has established itself as a reliable partner for switchgear construction, electrical installation, commissioning and maintenance. We offer our clients a broad portfolio of in-house production of electrical engineering, automation technology, process visualisation, switchgear construction and electrical MSR installation – always with the familiar exceptionally high quality standards of STELA.

In conversation with apprentices Johanna and Annalena:

What made you decide to start an apprenticeship at Stela?

We both knew for a long time that we wanted to work in an office. The open day at the new company building was also very interesting. You could see how the drying and switch systems are produced. The two companies not only produce products throughout Germany, but also deliver the systems worldwide.

What is different about your apprenticeship?

The special thing about our apprenticeship is that you learn a broad range of commercial knowledge. As you go through the different departments, you become more familiar with the different areas of work. This means that you get not only theoretical knowledge, but also practical experience. This is really helpful if you want to continue your education after the apprenticeship.

What does a typical day at Stela look like for you?

At Stela Laxhuber GmbH, it depends on which department you are in. Nonetheless, you are involved in the day-to-day business and allowed to handle cross-departmental tasks in order to better understand the internal processes. It's different at Stela Steuerungstechnik GmbH & Co. KG. As there are no departments here, you get to tackle different tasks every day. This means that you have to work independently every day.

What does training/continuing education look like at Stela Laxhuber GmbH and Stela Steuerungstechnik GmbH & Co. KG?

At the beginning of the apprenticeship, you take part in internal training courses to learn about the goods management system, company security and data protection. You can also take external training courses during or after the training if you wish. As an office management assistant, you can of course continue your training in a number of ways.

How does it work with vocational college? How often do you have to go there?

In the first year, you go to college twice a week. In your second and third year, classes are just once a week. The college is in Eggenfelden, which is very practical as it’s not far from here.

What are your plans for the future when your apprenticeship is finished?

We both want to work after our training to get more experience and learn routines. Then we both plan to continue with our education.