Drying plants for substitute fuels

Do you want to get the most out of your refuse-derived fuels? Then a flexible or individually adapted drying plant is recommended to achieve high added value and the best calorific values.

Fossil fuels are becoming an increasingly scarce and critically viewed commodity. The demand for alternatives is correspondingly high, also in order to achieve CO2 neutrality in the company. With efficient drying and appropriate further processing, these can be just as productive and uncomplicated to use as conventional energy sources.

Requirements for dryers for substitute fuels

Substitute fuels are also known as secondary or substitute fuels. These terms from the circular economy already make it clear that the source materials that fall under them can be diverse.

A large number of substitute fuels, which until a few decades ago were still referred to and treated as waste, have developed into the alternative raw materials that are so much in demand today, in particular due to improved, more efficient drying processes.

Due to the large number of source materials, drying is of particular importance here. Robust, flexible or even individually precisely adjusted drying technology is essential to achieve the best possible results for subsequent use. The requirements of the industry as the main customer are high.

Drying equipment tailored to the raw material optimises storability as well as processability and the calorific value of the product.

Our wide range of dryers and associated expertise is already contributing to optimised processes worldwide, conserving resources and making production sites more climate-friendly.

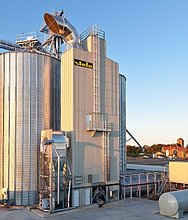

Drying plants for substitute fuels from Stela Laxhuber GmbH

The first products of Stela Laxhuber GmbH more than 100 years ago were wind wells. Sustainability, resource-saving management and CO2 reduction are therefore in our DNA.

Stela drying plants have always been manufactured in Germany, are technologically state-of-the-art, powerful, process-optimised, reliable, energy-efficient and have a high degree of efficiency.

If you are still unsure or have any questions, please do not hesitate to contact us. We look forward to advising you on your dryer project.