Pfeifer & Langen is widely known as one of Europe's leading sugar manufacturers.

2022 the company produced almost 1.9 million tons of sugar and agricultural products. This requires ultra-modern plants and environmentally friendly processes. Part of the process involves drying sugar beet pulp. Since last year, low-temperature drying has been realised with three STELA belt dryers.

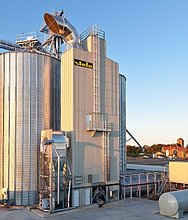

Pfeifer & Langen GmbH & Co. KG made a remarkable expansion at its Juelich plant in the past year by installing a new low-temperature dryer for sugar beet pulp, which was also integrated in the already existing pressed pulp transport route.

The decision to invest in the low-temperature dryer reflects Pfeifer & Langen GmbH & Co. KG ‘s long-term dedication to environmental compatibility and sustainability. These investments are not only a sign of corporate responsibility, but also a strategic response to the global challenges of climate change.

“The STELA drying system plays a key role in the realisation of our corporate goals. “

"The installation of the low-temperature dryers had a number of objectives in order to achieve the company's long-term goals," says Gerrit Boßmann, who works in the technical office at Pfeifer & Langen in Juelich, Germany. "On the one hand, it should serve to take the pressure off high-temperature drying and reduce its CO2 emissions. On the other hand, existing remaining energy should be used efficiently and odour emissions reduced." With an impressive water evaporation rate of up to 24.9 tonnes per hour, the STELA belt dryers set new standards in terms of sustainability and environmental protection at Pfeifer & Langen.

The collaboration with stela Laxhuber, which realised the low-temperature drying using three belt drying systems, was extremely positive from start to finish, says Boßmann. "We were extremely happy with the services provided and appreciate the efficiency and professionalism that stela brought to the collaboration."

This successful finalisation is an example of the fruitful collaboration between stela Laxhuber and its partners.

The three STELA belt dryers are combined to form a drying system with a total length of 90 metres and a width of 6.2 metres, with each dryer having a length of 30 metres. They are characterised by their special technical features, as they are equipped with three different heat sources that supply the hot water heat exchangers of the dryers. This technical equipment enables efficient and flexible drying of sugar beet pulp, depending on the locally available heat capacity. The total output of the dryers is approx. 24 [BG1] megawatts, which makes it possible to dry 75 tonnes of moist material per hour from an initial moisture content of 70% to a final moisture content of 55%.

The report on the new low-temperature drying system at Pfeifer & Langen GmbH & Co. KG serves not only as a reference for successful projects, but also as an inspiration for future initiatives in the field of sustainability and environmental protection in drying technology. It is proof that positive change is possible through targeted investment and cooperation.