MDB-XN 2-18-SU

in Ukraine

Products: Maize, Wheat

Dryer output capacity:

Maize: 50.8 t/h from 25% to 15%

Wheat: 104 t/h from 19% to 15%

Capacity / day:

40-45 t maize, 65-80 t grain

Dryer content:

up to max. 10,5 t

Connected load:

approx. 18 kW

Heating capacity:

930 kW direct

Capacity / day:

60-70 t maize, 100-120 t grain

Dryer content:

up to max. 16 t

Connected load:

approx. 30 kW

Heating capacity:

1.160 kW direct

Capacity / day:

100-120 t maize, 150-170 t grain

Dryer content:

up to max. 25 t

Connected load:

approx. 49 kW

Heating capacity:

1.744 kW direct

Capacity / day:

132-170 t maize, 264-300 t grain

Dryer content:

up to max. 44 t

Connected load:

approx. 68 kW

Heating capacity:

2.325 kW direct

*Drying capacities mentioned above related to maize (cleaned, biologically mature wet material, bulk density approx. 750 kg/m³) from 35% to 15%.

in 24 hours / grain (cleaned, biologically mature wet material, bulk density approx. 780 kg/m³) from 19% to 15% in 24 hours

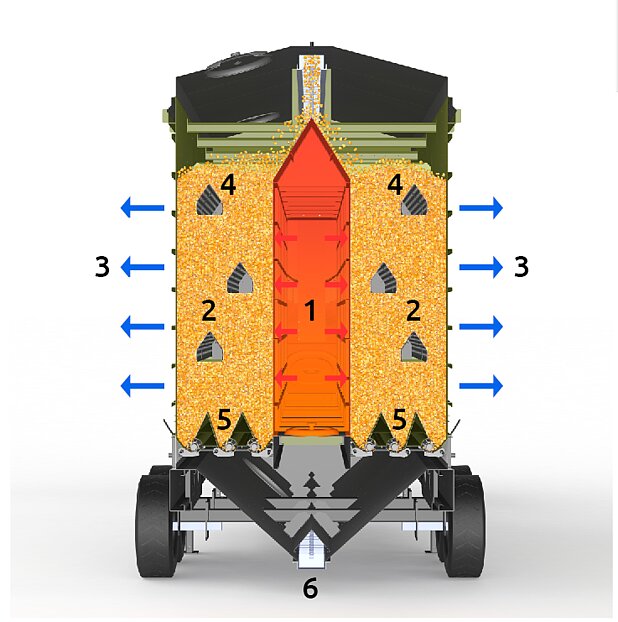

1 = Hot air

2 = Product

3 = exhaust air

4 = Relief roofs

5 = Roller discharge

6 = Elevator

Download here our information brochure.

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de