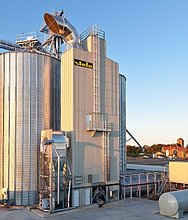

BT 1-6200-37.5

in Romania

Product: Sawdust

Dryer output capacity:

Sawdust: 11.6 t/h from 50% to 10%

Industry solutions

Products

About stela

Contact

What has long been state of the art in other sectors is now increasingly in demand in the timber industry: low-emission belt drying systems for pre- and main-drying of fibres, chips and OSB strands in chipboard production. It is a good thing that stela has been working intensively on waste wood drying for many years, since our customers can now benefit from this know-how through our drying systems: know-how based on efficiency, durability and the highest safety standards.

BT 1-6200-37.5

in Romania

Product: Sawdust

Dryer output capacity:

Sawdust: 11.6 t/h from 50% to 10%

BT 1-2700-8

in France

Product: Wood chips, sawdust

Dryer output capacity:

Wood chips, sawdust: 1.25 t/h from 50% to 10%

BT 1-6200-43.5

in Italy

Product: Wood chips

Dryer output capacity:

Wood chips: 9.6 t/h from 57% to 3%

BT 1-6200-34.5

in Canada

Product: Wood shavings, sawdust

Dryer output capacity:

Wood shavings, sawdust: 15.1 t/h from 44% to 8%

BT 1-6200-12

in Russia

Product: Sawdust

Dryer output capacity:

Sawdust: 3.6 t/h from 50% to 10%

BT 1-6200-61,50

in Chile

Product: Bark, sawdust

Dryer output capacity:

Bark, sawdust: 46 t/h from 64% to 49%

BT 1-6200-58.5

in Romania

Product: Sawdust

Dryer output capacity:

Sawdust: 17 t/h from 50% to 10%

BT 1-6200-16.5

in Canada

Product: Wood shavings, sawdust

Dryer output capacity:

Wood shavings, sawdust: 11.2 t/h from 37% to 8%

BT 1-6200-19.5

in Italy

Product: Sawdust

Dryer output capacity:

Sawdust: 6 t/h from 50% to 10%

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de

stela Laxhuber GmbH

Laxhuberplatz 1

D-84323 Massing

GPS coordinates:

North: 48.41839, East: 12.60456

Phone: +49 8724 899-0

Fax: +49 8724 899-80

Mail: office[at]stela.de

Web: www.stela.de

We use cookies on our website. Some of them are technically necessary, while others help us to improve this website or to provide additional functionalities.