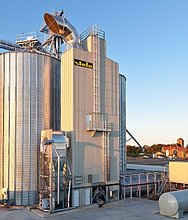

BT 1-6200-42

in Canada

Product: Sawdust

Dryer output capacity:

Sawdust: 14.8 t/h from 50% to 6%

Industry solutions

Products

About stela

Contact

The use of renewable raw materials to reduce CO2 emissions is indispensable for sustainable energy and environmental policy – our responsibility towards future generations. At stela, we have developed the optimum drying technology for natural biomass. In doing so we are building up regional added value as well as the use of waste heat from cogeneration plants for the drying.

BT 1-6200-42

in Canada

Product: Sawdust

Dryer output capacity:

Sawdust: 14.8 t/h from 50% to 6%

BT 1-6200-30

in Latvia

Product: Sawdust

Dryer output capacity:

Sawdust: 8.5 t/h from 50% to 10%

BT 1-6200-30

in Estonia

Product: Sawdust

Dryer output capacity:

Sawdust: 8.5 t/h from 50% to 10%

BT 1-6200-22.5

in Germany

Product: Sawdust

Dryer output capacity:

Sawdust: 7.5 t/h from 50% to 10%

BT 1-6200-19.5

in Germany

Product: Wood shavings, sawdust

Dryer output capacity:

Wood shavings, sawdust: 9.9 t/h from 44% to 13%

BT 1-6200-30

in Latvia

Product: Sawdust

Dryer output capacity:

Sawdust: 8.5 t/h from 50% to 10%

BT 1-6200-22.5

in Germany

Product: Sawdust

Dryer output capacity:

Sawdust: 6.5 t/h from 50% to 10%

BT 1-6200-13.5

in Croatia

Product: Sawdust

Dryer output capacity:

Sawdust: 5 t/h from 45% to 10%

BT 1-6200-30

in Germany

Product: Bark, sawdust

Dryer output capacity:

Bark, sawdust: 8 t/h from 50% to 9%

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de

stela Laxhuber GmbH

Laxhuberplatz 1

D-84323 Massing

GPS coordinates:

North: 48.41839, East: 12.60456

Phone: +49 8724 899-0

Fax: +49 8724 899-80

Mail: office[at]stela.de

Web: www.stela.de

We use cookies on our website. Some of them are technically necessary, while others help us to improve this website or to provide additional functionalities.