At stela Laxhuber, the service is just as convincing as the product itself.

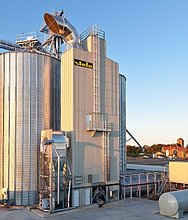

Every farmer can probably tell you a thing or two about the fact that not everything in life goes according to plan - and so can every agricultural trade. At the end of 2021, the Unkrüer family business was faced with the challenge of having to procure a new dryer for the next harvest season as quickly as possible. In less than a year, there would again be plenty of maize and grain to dry. Due to the long and good cooperation with stela Laxhuber, Wilhelm and Hubertus Unkrüer therefore again decided on a system from Massing. From the careful planning to the rapid delivery and installation in Langenberg, North Rhine-Westphalia, to the flawless operation, the brothers have nothing but praise for this order as well.

In the middle of the harvest season, the main dryer at Landhandel Unkrüer 2021 broke down completely. But the brothers Wilhelm and Hubertus didn't let that get them down. On the one hand, the second dryer - also from stela - ran at full speed for the rest of the season. "This relatively small dryer has probably never had as much throughput as it had that year," Wilhelm Unkrüer speculates with a smile. "Even at stela they were impressed that it managed around 6,000 tonnes."

That speaks for itself, and so they asked their long-time stela contact Christoph Hoefler and his team for the quick delivery of a new dryer. In order to be at the cutting edge in terms of energy efficiency, the larger Biturbo version was chosen, which dries particularly gently and evenly with reduced energy consumption thanks to its ingenious airflow.

3D calculation to the centimetre

"A particular challenge for us was the limited space," explains Hubertus Unkrüer. The older and smaller dryer had fit easily between various already existing buildings and silos. The new building now had to fit in as well. “It was very impressive how Mr Hoefler could immediately see from a three-dimensional model that the connection to the already existing gutter had to be moved slightly so that the pipe was not planned directly through a steel beam.“ And the various accesses and ladders were also inserted with precision. "You really can see the extensive experience and know-how that stela has to offer," compliments Wilhelm Unkrüer.

Just put it in

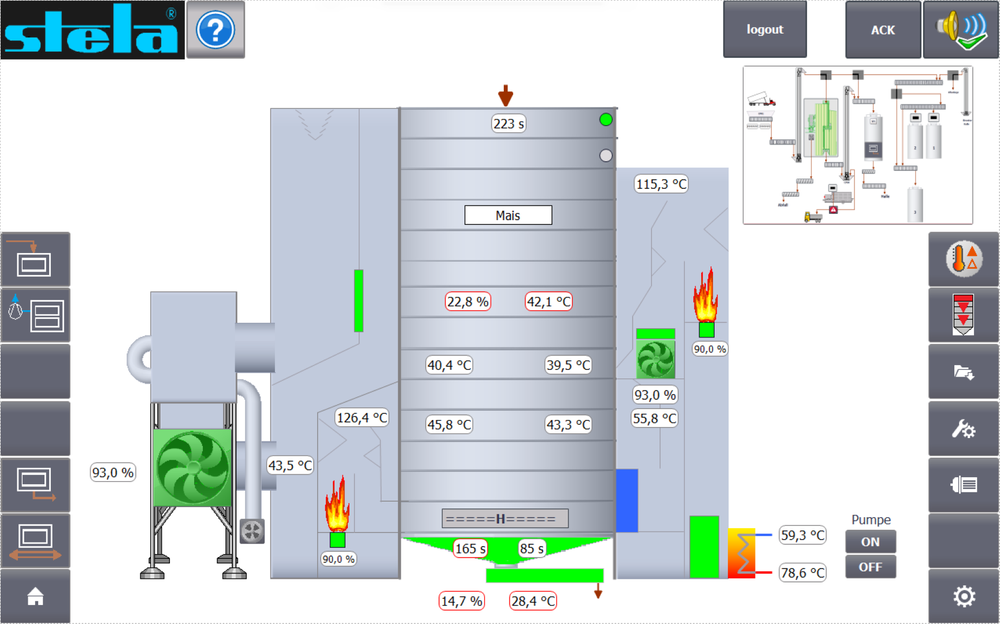

However, the investment is not only convincing in the start-up phase, but also in continuous operation. In 2022, the maize harvest was plentiful and in 2023 a high percentage of the grain harvest had to be dried. The new dryer was thus able to prove itself right away in the daily routine of the classic agricultural business and process 840 t per day. Wilhelm Unkrüer explains: "The optimal burner position and ingenious air flow, which is guided through the material to be dried several times from two sides, ensure truly economical operation and a reliably good drying result. We have just had a very wet grain harvest and did not have to think twice about any condition: Just put it in and the result was always 14 to 15% residual moisture.” Hubertus Unkrüer adds: “And switching between different drying goods also works smoothly.“

And the integration of the existing heat sources - natural gas and biogas - also took place without complaint. "The heat exchanger provides additional energy efficiency and an additional ventilation system has even been installed in case the main ventilation should become blocked. Then the control system also intervenes automatically," adds Hubertus Unkrüer.

Readjustment at the lunch table

Wilhelm Unkrüer is particularly excited about the dryer's control system. "For one thing, all the relevant machines were integrated directly. This means we can also reach the second dryer and the silos, for example. The set-up is also very intuitive and the pre-settings were immediately right. If you select the correct parameters, the machine controls itself and you never wonder where to press when you want to check or adjust something. And you can even do it all via app from your smartphone - literally at the lunch table."

Convinced regular customers

“There is of course a reason why we have been stela customers for 30 years,“ Hubertus Unkrüer emphasises. "The extremely structured and precise way of working impressed us once again - as did the clean site management. We started with the specific planning in January 2022 and the system was up and running in September. Within a very short period of time, the installation team had everything set up and adjusted. It has been running since. And if something does go wrong, the service is not only available 24/7. It also actively looks for the best possible solution and accompanies it until the end.”

21. September 2023

Pictures: Dinah Urban / stela Laxhuber Gmbh