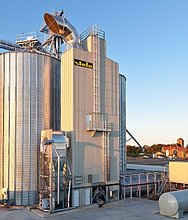

Stela offers the perfect solution for any drying task

Stela is specialized in drying systems and technologies. Thanks to years of experience, we always know exactly what our customers need. We will provide the optimal solution for you and deliver drying systems individually by customer request.

Drying plants from Stela at an overview

Drying systems and drying technologies made in Germany!

Since the production of the first driers in 1967, STELA Laxhuber GmbH has developed and established itself as a leading and globally active industrial company in the field of drying plant construction.

We are an internationally active company that sets standards in the field of drying technologies with sustainable success. With over 4,000 realised plants operating in various countries of the world, we are commonly referred to as the technology leader for drying plants.

Our portfolio includes a range of individual solutions that we, as mechanical engineers in Lower Bavaria, continuously improve and develop.

For example: 43 million tons of pourable arable crops – that is the amount dried worldwide with stela drying plants every year. An unimaginable number, the result of years of hard work. If you look at these quantities, you can see how important quality and functionality of a system is.

In addition to agriculture, our drying systems are used in the food industry, the pellet industry as well as in the waste disposal industry and water management.

For medium and large power ranges up to 25 tons of water evaporation per hour for example, our low-temperature belt dryer BT is suitable. The stela low-temperature belt dryer BTL is perfect for small and medium power ranges up to 5 tons of water evaporation per hour. If your focus lies on emission control and exhaust air minimisation, our velt dryer type BTU RecuDry® with exhaust air condensation is the ideal solution.

Get an overview of our drying systems now.

Our references

Our services

As a developer and manufacturer, we accompany our systems from the planning stage to the functional handover and continue to monitor their performance while in use at the customer's site. In addition to our staff, we continue to share our knowledge by providing maintenance and spare parts services throughout the entire life cycle of the system, long after the original investment project phase has ended.

stela drying technology – a world leader

Since the production of the first dryer in 1967, stela has developed into a leading and globally active industrial company in the field of drying system construction.

Contact person

Low temperature, continuous dryer, circulating dryer – not sure what’s the best choice for you? Our experienced colleagues will be happy to help you find the best solution for your product. Please feel free to contact us without obligation.

Telephone +49 8724 899-10

Email sales[at]stela.de